Lime production: improved techniques in Malawi

Practical Action

The slightly moist and hot slaked lime (calcium hydroxide, Ca(OH)2) is then allowed to dry

and cool for a period of 24 hours.

The lime is then sieved into plus or minus 5mm fractions with the latter retained, and about

11 %, being waste material.

The product from sieving is then milled in a hammer mill powered by a diesel engine, of the

type normally used for milling maize. The milling is done in order to produce a fine and

uniform product.

The milled hydrated lime is then bagged by hand.

The quality of the lime produced averages 60% available lime content. (Available lime

content is the measure normally used to compare the quality of limes. It means the amount

of chemically active freelime and is expressed as the calcium oxide or CaO content. In a

hydrated lime the theoretical maximum available lime content is 75%.)

Mechanical and air classification equipment, designed for this particular plant, is currently

being tested.

Mode of operation

The kiln operates on a

continuous 24 hour per day

basis. Although it is possible

to operate a kiln of this type

in fairly short production

runs of a few days,

considerable effort and

energy is wasted every time

the kiln is allowed to cool

down and has to be

restarted.

Production should, therefore,

be continuous with only

occasional shut downs for

maintenance and repair.

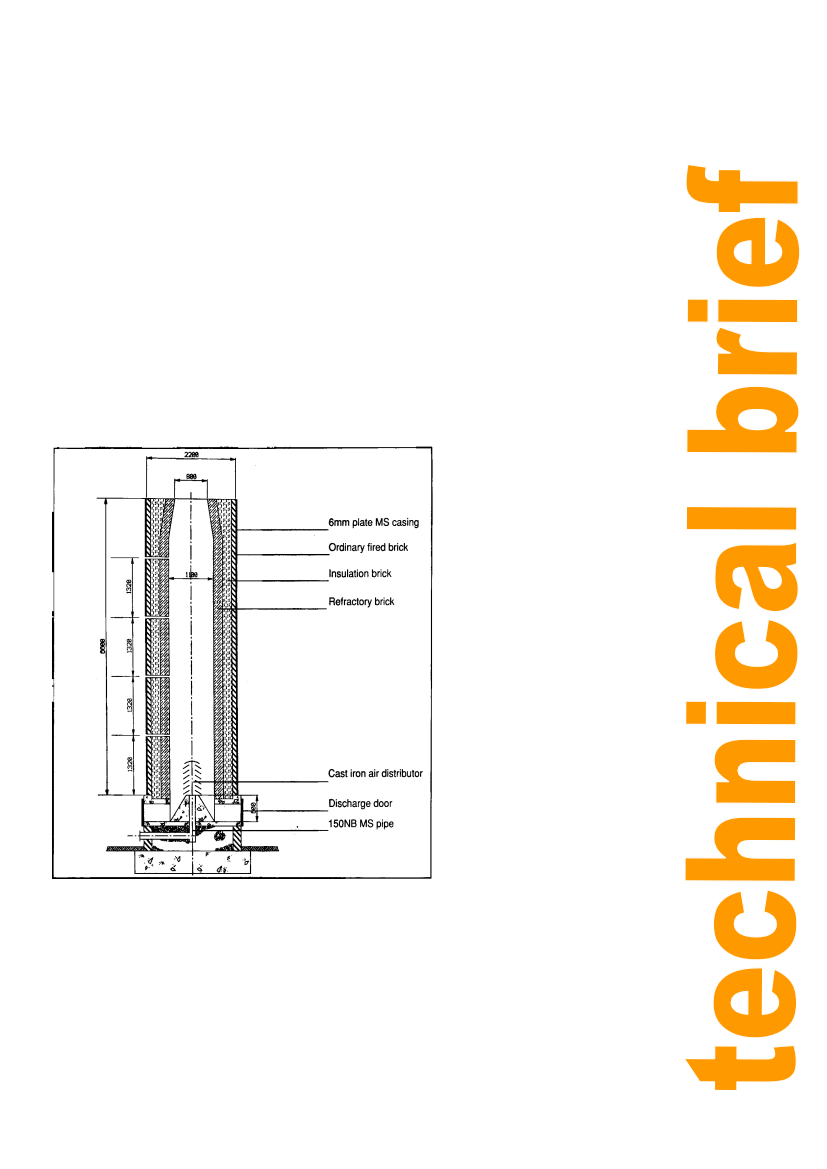

Figure 3: Technical detail of improved kiln design.

The associated activities

such as quarrying, hydrating

and bagging are, in this

particular case, only

undertaken during the day-

time shift.

Comments

One of the major issues of this particular lime production unit is its location. It was decided

to site the kiln at the town of Balaka, over 15 km from the quarry site on grounds that the

advantages of being close to power, water supplies and communications would outweigh the

disadvantage of needing to transport marble from the quarry to the kiln site. While this

decision may have been correct in the short term it is likely to prove economically

advantageous to site the kiln close to the quarry once water and power facilities are provided

at Chenkumbi.

3